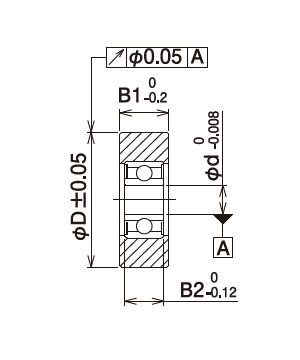

Plastic mold bearing

Features

It is a plastic mold bearing using JIS standard 69 series bearings with high load capacity. It is made of insert molding, and the width of the plastic mold wider than the bearing, and the pull-out strength is increased. Since polyacetal resin is used and the outer diameter surface is machining finished, smooth and swinging accuracy is also good. There is also an inner ring creep free plastic mold bearing with the same size, with a creep prevention ring. Flat type outer dia. profile is standard, but it can also correspond to V groove or U groove.

Application example

- Printer

- Copying machine

- Conveyor device

{{alertMsg_unit_1}}

{{msgMsg_unit_1}}

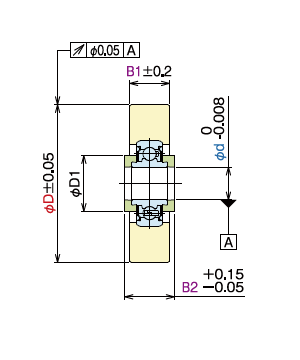

Creep free

Features

It is bearing molded of polyacetal resin on the outer ring of a miniature ball bearing. It is a bearing in which an anti-creep ring is attached to the inner ring of the bearing to improve creep resistance between the inner ring inner diameter and the shaft. Easier installation by making the inner ring width larger than the outer diameter width. Outer ring resin is increasing push out force by insert molding. Material for the outer ring resin is polyacetal basically, but it also corresponds to other resins. Standard outer profile is straight , but V groove or U groove are also available.

Application example

- PPC

- Printer

- FAX

{{alertMsg_unit_4}}

{{msgMsg_unit_4}}

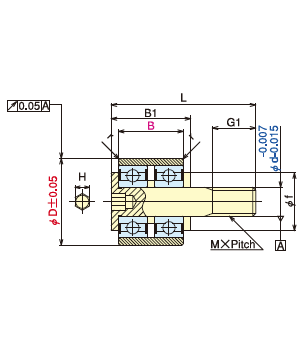

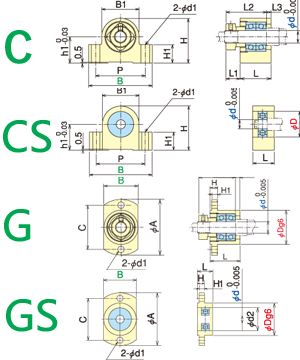

Guide follower

Features

We offer extremely small guide followers using our company's high precision miniature ball bearings.

- Low friction torque

Low friction because it uses miniature ball bearings. - There is no looseness.

Since the bearing is incorporated with preload controlled, the roller will not looseness.

Application example

- Small conveying device

{{alertMsg_unit_2}}

{{msgMsg_unit_2}}

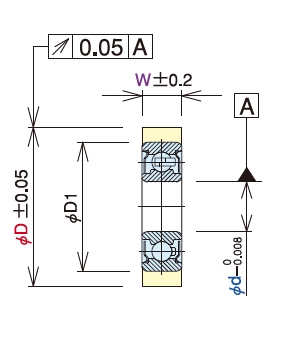

Urethane bearing

Features

Urethane bearings are baked and glued with urethane rubber directly on the outer rings of miniature ball bearings. It corresponds to the use of a feed mechanism that requires high precision, low vibration, and low noise.

- Rubber is directly baked and glued to the outer diameter of the bearing.

- The outer diameter is polished finish.

- High accuracy, low vibration, low noise.

- Standard dimension items are available.

- It also corresponds to other dimensions, special dimensions, material change.

Application example

- ATM

- Ticket-vending machine

{{alertMsg_unit_3}}

{{msgMsg_unit_3}}

Croxport

Features

Light weight and compact

- Weight reduction by 60% (comparison of croxport MSU-6C)

- Contributing to downsizing of equipment, weight saving, high responsiveness

- Miniature angular contact ball bearing Croxy series which precisely controlled preload is mounted and realizes higher axial stiffness.

- The axis height is the same as the standard

- Axial load performance is equal or higher (all model number)

Application example

- Ball screw support

{{alertMsg_unit_5}}

{{msgMsg_unit_5}}

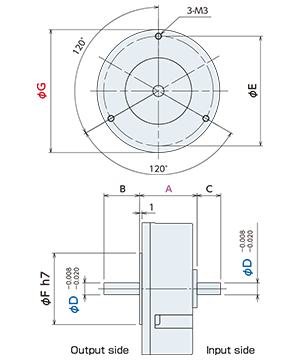

Traction drive

Characteristics

Roller type reducer equipped with in-house high precision miniature ball bearing.

Low vibration and low noise with high roration by small energy loss.

Low vibration and low noise with high roration by small energy loss.

- Reduction ratio 10(One-stage speed reduction)

- Rotation is even

- Low backlash

- Low vibration and low noise.

Application

- Small type robot

- Drone

- Industrial Machine

{{alertMsg_unit_8}}

{{msgMsg_unit_8}}

- Please select the line to download and click "Download" button.

- If the CAD file does not exist, please note that even if you press the button, it will not be downloaded.

- If an error occurs during download, there may be a cause in the transmission environment. Please try again after the lapse of time or from another terminal.

Note on use

NSK Micro Precision Co., LTD.

Sales department customer support

TEL:03-5283-7420 FAX:03-5259-0882

E-Mail:contact1@nskmicro.co.jp

URL:https://www.nskmicro.co.jp/

Request when using CAD data

If you use (replicating) CAD data, we understand that you have accepted the following conditions.- The copyright of NSK Micro Precision Co.,Ltd. is existing in CAD Data.

Copying and transffering of CAD data are limited with following conditions

1) Copying of CAD data is allowed only back up purpose.

2) Transferring of CAD data to 3rd party is allowed only in case NSK Micro Precision CO., Ltd agrees.

- You should take responsible for CAD data selection, use and its results.

- Modification of CAD data is prohibited in principle. If any change is made, it is your responsibility for the result of using it.

Contact about CAD data

6F Hirose Bldg., 3-17 Kanda-nishiki cho, Chiyoda-ku, Tokyo 101-0054NSK Micro Precision Co., LTD.

Sales department customer support

TEL:03-5283-7420 FAX:03-5259-0882

E-Mail:contact1@nskmicro.co.jp

URL:https://www.nskmicro.co.jp/

System Version 3.4.0.0